-

Plastic Injection Molding Parts

-

Structural Foam Injection Moulding

-

Gas Assisted Injection Moulding

-

Plastic Injection Overmolding

-

Toolmaking Services

-

Rapid Prototype Tooling

-

3D Printing Rapid Prototyping Services

-

Vacuum Casting Prototype

-

CNC Machining Parts

-

Sheet Metal Rapid Prototyping

-

Surface Finishing Services

-

Pressure Die Casting Parts

-

Nate G.I really appreciated your working with us on the change and all throughout the process. If there's a possibility to give positive feedback, I'd love to do so. It's been great working with Haoshun so far!

Nate G.I really appreciated your working with us on the change and all throughout the process. If there's a possibility to give positive feedback, I'd love to do so. It's been great working with Haoshun so far! -

Kevin W.We received your package of the molded parts. They look and function GREAT, so thank you very much. We are very impressed with your quality!

Kevin W.We received your package of the molded parts. They look and function GREAT, so thank you very much. We are very impressed with your quality! -

Mr. G. TaylorWe greatly appreciate your team's support and the quality of the work. I'm super happy by your service and quality, thank you very much!

Mr. G. TaylorWe greatly appreciate your team's support and the quality of the work. I'm super happy by your service and quality, thank you very much!

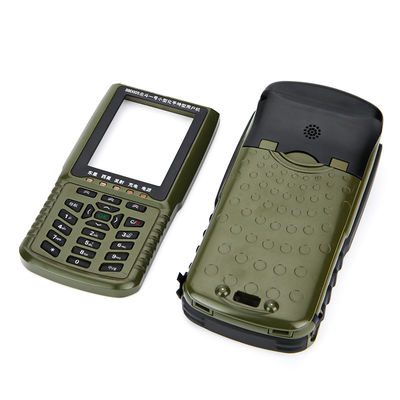

Customized Plastic Injection Molding Parts with Surface Finishes

| Place of Origin | Guangzhou, Guangdong |

|---|---|

| Brand Name | N/A |

| Certification | ISO9001 |

| Model Number | Custom |

| Minimum Order Quantity | 1 |

| Price | TBD |

| Packaging Details | Pearl cotton wrapped products into cartons |

| Delivery Time | 7~15 working days |

| Payment Terms | 50% deposit payment upon ordering, 50% balance before shipment |

| Supply Ability | Plastic injection molding parts, plastic injection mold |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Certificate | ISO9001 | Critical Tolerance | ±0.05mm |

|---|---|---|---|

| Design | .STEP 3D / 2D Drawing | MOQ | No MOQ Requirement |

| Logo | Customized | Surface Finish | Polishing, Sandblasting, Texture, Painting, Etc. |

| Application | Automotive, Medical, Electronic, Household, Etc. | Package | Carton, Wooden Pallet, Etc. |

Customized Plastic Injection Molding Parts with Surface Finishes

Product Description:

Our plastic injection molding parts are available in a variety of sizes, shapes, and colors, and are perfect for a wide range of applications. Whether you need plastic injection molding parts for automotive, electronics, medical, or industrial applications, we have the expertise and experience necessary to meet your needs.

One of the key benefits of our plastic injection molding parts is that they have no MOQ requirement. This means that you can order the exact number of parts that you need, without having to worry about over-ordering or under-ordering. We understand that every customer has unique needs, and we are committed to providing the flexibility and customization that our customers need to succeed.

Our plastic injection molding parts are also available in a variety of packaging options, including carton, wooden pallet, and more. We understand that our customers have different shipping and storage needs, and we are committed to providing the packaging options that best meet those needs.

In addition, we offer customized logo options for our plastic injection molding parts. We understand that branding is important to our customers, and we are committed to providing the branding options that our customers need to succeed. Whether you need your logo printed, etched, or otherwise customized onto your plastic injection molding parts, we have the expertise and experience necessary to make it happen.

Our lead time for plastic injection molding parts is typically 15-30 days. We understand that our customers need their parts in a timely manner, and we are committed to providing the fast and reliable service that our customers need to succeed.

Finally, our plastic injection molding parts are designed to meet critical tolerance requirements, with a tolerance of ±0.05mm. We understand that precision is key in many applications, and we are committed to providing the level of precision and accuracy that our customers need to succeed.

In summary, our plastic injection molding parts are the perfect choice for customers who need high-quality, customizable, and flexible parts for a wide range of applications. With no MOQ requirement, a variety of packaging options, customized logo options, a fast lead time, and critical tolerance requirements of ±0.05mm, our plastic injection molding parts are the best choice for your needs.

Features:

- Product Name: Plastic Injection Molding Parts

- Package: Carton, Wooden Pallet, Etc.

- Certificate: ISO9001

- Logo: Customized

- Design: .STEP 3D / 2D Drawing

- Surface Finish: Polishing, Sandblasting, Texture, Painting, Etc.

Technical Parameters:

| Package: | Carton, Wooden Pallet, Etc. |

| Surface Finish: | Polishing, Sandblasting, Texture, Painting, Etc. |

| Certificate: | ISO9001 |

| Shape: | As Per Drawing |

| Process: | Injection Molding |

| Color: | Customized |

| Lead Time: | 15-30 Days |

| Design: | .STEP 3D / 2D Drawing |

| MOQ: | No MOQ Requirement |

| Critical Tolerance: | ±0.05mm |

Applications:

The Plastic Injection Molding Parts can be used in a variety of applications and scenarios. They are extensively used in the manufacturing of consumer products like toys, kitchenware, electronic devices, and household appliances. These parts have great durability and strength, making them ideal for use in the automotive and aerospace industries. They are also used in the medical and healthcare industry for the production of medical devices and equipment.

These Plastic Injection Molding Parts have a wide range of colors available and can be customized as per the client’s needs. The materials used to make these parts include ABS, PC, PC/ABS, Nylon, POM, PMMA, PEEK, and many more. These materials have different properties that make them suitable for different applications. The Plastic Injection Molding Parts have no minimum order quantity requirement, and they have a lead time of 15-30 days.

The Plastic Injection Molding Parts come with pearl cotton wrapped products into cartons packaging. The delivery time for these parts is 7~15 working days, and a 50% deposit payment is required upon ordering, with the balance of 50% due before shipment. These parts have a great supply ability and can be used in various product applications and scenarios. If you need high-quality plastic injection molding parts, then these custom-made parts are a perfect fit for your needs.

Customization:

Our plastic injection molding parts are fully customizable to meet your specific needs. We offer a wide range of options, including custom models, colors, and applications. All of our products are manufactured in Guangzhou, Guangdong and are certified with ISO9001 quality standards.

Our minimum order quantity is 1 unit, with pricing to be determined based on your customization requirements. Our packaging includes pearl cotton wrapping and cartons for safe transportation. Delivery time is typically 7-15 working days, and we require a 50% deposit payment upon ordering with the remaining 50% balance due before shipment.

We are committed to delivering high-quality products with a supply ability for both plastic injection molding parts and molds. Our lead time is 15-30 days and we offer critical tolerance of ±0.05mm. Our products are suitable for a variety of industries, including automotive, medical, electronic, household, and more.

With our ISO9001 certification and commitment to customization, we are confident that we can provide the perfect plastic injection molding part for your needs.

Support and Services:

Our Plastic Injection Molding Parts product comes with a comprehensive technical support and services package to ensure that our customers get the most out of their purchase. Our team of experts is available to answer any questions or concerns you may have about the product and its usage. We also offer customized solutions to meet your unique needs and requirements.

In addition, we provide maintenance services to keep your Plastic Injection Molding Parts in top condition and extend its lifespan. Our team can help with repairs, replacements, and upgrades as needed.

We are committed to providing excellent customer service and support throughout the entire process, from initial inquiry to post-purchase support. Contact us to learn more about our product technical support and services.

Packing and Shipping:

Product Packaging:

All plastic injection molding parts are carefully packed to ensure safe and secure delivery. Each part is individually wrapped in bubble wrap and then placed in a sturdy cardboard box. The box is tightly sealed to prevent any damage during shipment.

Shipping:

We offer worldwide shipping for our plastic injection molding parts. Shipping fees will vary depending on the destination and the size of the order. Our standard shipping method is by air, but we can also arrange for sea or land transportation upon request. Delivery time will depend on the shipping method and destination, but we strive to deliver all orders in a timely and efficient manner.