-

Plastic Injection Molding Parts

-

Structural Foam Injection Moulding

-

Gas Assisted Injection Moulding

-

Plastic Injection Overmolding

-

Toolmaking Services

-

Rapid Prototype Tooling

-

3D Printing Rapid Prototyping Services

-

Vacuum Casting Prototype

-

CNC Machining Parts

-

Sheet Metal Rapid Prototyping

-

Surface Finishing Services

-

Pressure Die Casting Parts

-

Nate G.I really appreciated your working with us on the change and all throughout the process. If there's a possibility to give positive feedback, I'd love to do so. It's been great working with Haoshun so far!

Nate G.I really appreciated your working with us on the change and all throughout the process. If there's a possibility to give positive feedback, I'd love to do so. It's been great working with Haoshun so far! -

Kevin W.We received your package of the molded parts. They look and function GREAT, so thank you very much. We are very impressed with your quality!

Kevin W.We received your package of the molded parts. They look and function GREAT, so thank you very much. We are very impressed with your quality! -

Mr. G. TaylorWe greatly appreciate your team's support and the quality of the work. I'm super happy by your service and quality, thank you very much!

Mr. G. TaylorWe greatly appreciate your team's support and the quality of the work. I'm super happy by your service and quality, thank you very much!

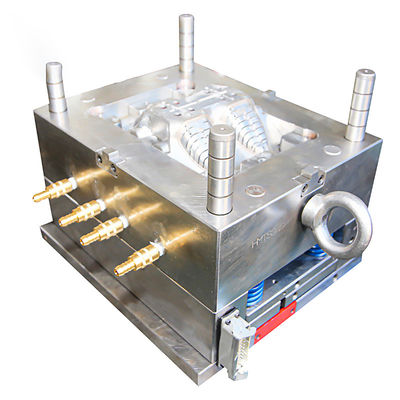

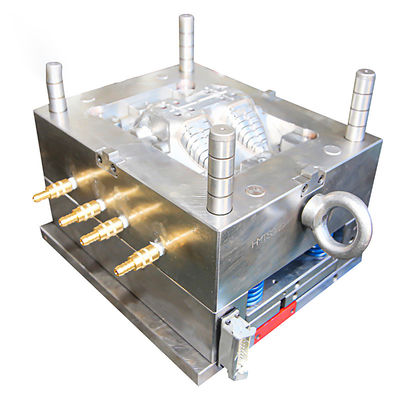

Steel Custom Cold Runner Injection Mold Making Service with 10K~1000K Mold Life

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Tolerance | +-0.1mm | Mold Life | 10K~1000K |

|---|---|---|---|

| Materials Used | Steel For The Molds, Plastic For The Parts | Sample | 12 PCS T1 Free Samples |

| Gate Type | Edge Gate | Runner | Hot Runner, Cold Runner |

| Model Numbe | Custom | Color | White, Customized |

Steel Custom Cold Runner Injection Mold Making Service with 10K~1000K Mold Life

Product Description:

One of the main materials we use for our Toolmaking Services is steel material 738. This high-quality steel is known for its durability and strength, making it the perfect material for creating tools and molds that will last for years to come.

To ensure that our customers are completely satisfied with our Toolmaking Services, we offer 12 PCS T1 Free Samples. This allows you to test our products and see the quality of our work before committing to a larger order.

Our production process for our Toolmaking Services includes several steps to ensure the highest quality outcome. We start with design, where our team of experts will work with you to create a design that meets your specific needs. From there, we move on to prototyping, where we will create a prototype of your design to ensure that it meets your expectations. Once the prototype is approved, we move on to machining, where we will create the tool or mold using state-of-the-art machinery. Finally, we finish the product to ensure that it meets our high standards and is ready for use.

When it comes to the lifespan of our molds, you can rest assured that they will last for a long time. Our molds have a lifespan of 10K~1000K, ensuring that you get the most out of your investment.

Our Toolmaking Services also include the option of an edge gate for your molds. This gate type is perfect for creating high-quality injection molds that will meet your specific needs.

Overall, our Toolmaking Services are designed to provide you with the highest quality Injection Mould Manufacturing services on the market. From our use of high-quality materials to our state-of-the-art production processes, we are dedicated to providing you with the best possible outcome for your specific needs.

Features:

- Product Name: Toolmaking Services

- Materials Used:

- Steel

- Plastic

- Runner:

- Hot Runner

- Cold Runner

- Steel Material: 738

- Lead Time: Varies Depending On Complexity And Quantity

- Production Process:

- Design

- Prototyping

- Machining

- Finishing

Our Toolmaking Services specialize in Plastic Mould Making and Toolmaking. We use high-quality materials including steel and plastic, and offer both hot and cold runner options. Our steel material is 738 and our production process includes design, prototyping, machining, and finishing. Lead time varies depending on complexity and quantity.

Technical Parameters:

| Product Attribute | Value |

| Product Name | Toolmaking Services |

| Material | PC+ABS, Customized |

| Steel Material | 738 |

| Gate Type | Edge Gate |

| Model Number | Custom |

| Tolerance | +/-0.1mm |

| Lead Time | Varies Depending On Complexity And Quantity |

| Sample | 12 PCS T1 Free Samples |

| Materials Used | Steel, Plastic |

| Color | White, Customized |

| Mold Life | 10K~1000K |

Applications:

Our Toolmaking Services come with a minimum order quantity of 1 mold or die, and our pricing is TBD. We package our Toolmaking Services in wooden crates to ensure they are protected during transportation.

Our delivery time is approximately 20~30 working days, and we require a 50% deposit upon ordering, with the remaining 50% balance payment due before shipment.

We offer two types of runners: hot runner and cold runner. Our Steel Material is 738, and our Mold Life is between 10K~1000K.

Our Toolmaking Services are versatile and can be used to create a variety of products. We use both steel and plastic materials, and our Model Number is custom-made to meet the specific needs of our clients.

Our Toolmaking Services are perfect for companies that require high-quality, precise molds and dies to produce their products. Our services will help streamline the manufacturing process and ensure that products are produced to the highest quality standards.

Customization:

Our Injection Mold Making services include Tooling Manufacturing and Injection Tooling Making. We offer customization services for our molds to meet your specific needs. Our molds are made in Guangzhou, Guangdong and are ISO 9001 certified for quality assurance. The minimum order quantity is 1 and price is to be determined based on your specific requirements. Packaging details include a wooden crate for safe delivery and the delivery time is estimated at 20-30 working days. Payment terms require a 50% deposit upon ordering and a 50% balance payment before shipment. Our molds can be made with either Hot Runner or Cold Runner systems and can have Pin Point Gate, Edge Gate or Sub Gate methods. We offer a variety of colors including white and custom options. The production process includes design, prototyping, machining and finishing to ensure high quality molds tailored to your needs.

Support and Services:

Our Toolmaking Services product comes with comprehensive technical support and services to ensure the best performance and longevity of your tools. Our experienced team of technicians is available to provide assistance and guidance with any questions or issues you may have.

We offer a range of services including tool maintenance, repair, and refurbishment. Our team utilizes the latest technologies and equipment to provide high-quality services that meet the unique needs of each client.

In addition, we provide training and education on tool maintenance and operation to help our clients maximize the lifespan and efficiency of their tools. Our goal is to provide reliable and cost-effective solutions to ensure the success of your business.