-

Plastic Injection Molding Parts

-

Structural Foam Injection Moulding

-

Gas Assisted Injection Moulding

-

Plastic Injection Overmolding

-

Toolmaking Services

-

Rapid Prototype Tooling

-

3D Printing Rapid Prototyping Services

-

Vacuum Casting Prototype

-

CNC Machining Parts

-

Sheet Metal Rapid Prototyping

-

Surface Finishing Services

-

Pressure Die Casting Parts

-

Nate G.I really appreciated your working with us on the change and all throughout the process. If there's a possibility to give positive feedback, I'd love to do so. It's been great working with Haoshun so far!

Nate G.I really appreciated your working with us on the change and all throughout the process. If there's a possibility to give positive feedback, I'd love to do so. It's been great working with Haoshun so far! -

Kevin W.We received your package of the molded parts. They look and function GREAT, so thank you very much. We are very impressed with your quality!

Kevin W.We received your package of the molded parts. They look and function GREAT, so thank you very much. We are very impressed with your quality! -

Mr. G. TaylorWe greatly appreciate your team's support and the quality of the work. I'm super happy by your service and quality, thank you very much!

Mr. G. TaylorWe greatly appreciate your team's support and the quality of the work. I'm super happy by your service and quality, thank you very much!

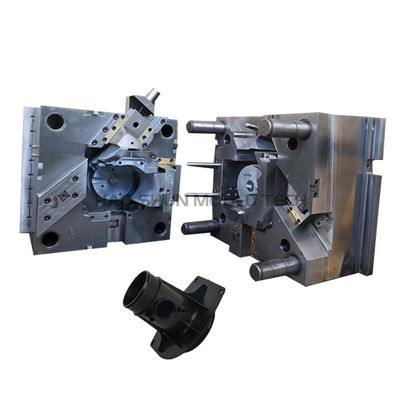

Toolmaking Services for Custom Plastic Models Pin Point Gate Method Included

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Tolerance | +-0.1mm | Lead Time | Varies Depending On Complexity |

|---|---|---|---|

| Materials Used | Steel, Plastic | Production Process | Design, Prototyping, Machining, Finishing |

| Gate Method | Pin Point Gate | Material | PC+ABS, Customized |

| Steel Material | 738 | Sample | 12 PCS T1 Free Samples |

Toolmaking Services for Custom Plastic Models Pin Point Gate Method Included

Product Description:

Our team of experts are highly skilled in creating products with precision, ensuring that every product is made with a tolerance of +-0.1mm, and that every detail is accounted for. We understand that every product is unique, and we take the time to work with our clients to ensure that we meet their specific needs.

Our Toolmaking Services utilize an edge gate system, ensuring that the finished product is of the highest quality. Additionally, we offer a wide range of colors, including white, and can also customize colors to fit our clients' needs. We believe that our clients should have the freedom to choose the color of their products, and we're happy to accommodate their requests.

We also utilize a pin point gate method, which helps to ensure that the finished product is of the highest quality. This method helps to minimize any potential defects and ensures that the product is consistent in quality from start to finish.

Our Toolmaking Services are perfect for businesses looking to create high-quality, custom-made products. Whether you're looking to create a prototype or a finished product, we have the expertise and experience needed to ensure that your product is made to the highest standard.

Features:

- Product Name: Toolmaking Services

- Mold Life: 10K~1000K

- Production Process: Design, Prototyping, Machining, Finishing

- Materials Used: Steel, Plastic

- Gate Type: Edge Gate, Pin Point Gate, Sub Gate

Technical Parameters:

| Product Attribute | Value |

|---|---|

| Product Name | Toolmaking Services |

| Injection Die Making | Yes |

| Injection Mould Manufacturing | Yes |

| Material | PC+ABS, Customized |

| Runner | Hot Runner, Cold Runner |

| Production Process | Design, Prototyping, Machining, Finishing |

| Lead Time | Varies Depending On Complexity And Quantity |

| Mold Life | 10K~1000K |

| Steel Material | 738, 2316, 2344, etc. |

| Materials Used | Steel, Plastic |

| Model Number | Custom |

| Color | White, Customized |

| Tolerance | +/-0.1mm |

Applications:

The Toolmaking Services product is ideal for various application occasions and scenarios. It is suitable for injection mould manufacturing, which means it can be used to create different types of plastic parts. Companies that specialize in plastic products can benefit from this product as it offers an efficient and cost-effective solution for toolmaking.

One of the key features of our Toolmaking Services product is its gate method. The Pin Point Gate allows for precise injection of the molten material into the mould, ensuring a high level of accuracy and consistency. This is particularly useful for small and intricate parts that require a high degree of precision.

The lead time for the Toolmaking Services product varies depending on complexity and quantity. However, we always strive to deliver our products within the shortest possible time while maintaining the highest quality standards. We understand that time is of the essence, and we work hard to ensure that our customers receive their orders on time.

The Toolmaking Services product comes with a custom model number and a tolerance level of +-0.1mm. This means that the product is tailored to meet the specific needs of our customers, ensuring that they receive a solution that fits their requirements perfectly. Our team of experts works closely with our customers to ensure that they get the best possible product.

In conclusion, our Toolmaking Services product is a must-have for companies that specialize in plastic products. It offers an efficient and cost-effective solution for Injection Mould Manufacturing and Toolmaking. With its Pin Point Gate method, custom model number, and high tolerance level, our product is the perfect solution for creating small and intricate plastic parts. Get in touch with us today to learn how our Toolmaking Services product can benefit your business.

Customization:

Our Injection Die Making, Injection Mould Manufacturing, and Injection Tooling Making services come with the option of Product Customization. We offer customization services for the following product attributes:

- Color: White, Customized

- Material: PC+ABS, Customized

- Assembly Process: Ultrasonic Welding

- Gate Type: Edge Gate

- Tolerance: +-0.1mm

- Place of Origin: Guangzhou, Guangdong

Support and Services:

Our Toolmaking Services product is backed by comprehensive technical support and services to ensure that our customers can fully maximize the potential of our tools. Our team of experts is available to answer any technical questions and provide guidance on tooling solutions. We also offer maintenance and repair services to keep your tools in top condition, as well as customization services to meet specific tooling needs. Additionally, we provide training and education services to help operators and technicians optimize tool usage and achieve better results. Trust us to provide the support and services needed for your toolmaking needs.

Packing and Shipping:

Product Packaging:

The toolmaking services product will be securely packaged in a wooden crate with appropriate padding and protection to prevent damage during transportation.

Shipping:

We offer standard air/sea/ground shipping for all toolmaking services parts. Shipping rates may vary depending on the destination and weight of the package. Customers will receive a shipping details once the mold has been shipped.